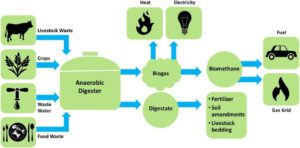

Biogas is a type of gas that can be produced from organic waste. It’s produced by anaerobic digestion, which is the breakdown of organic matter in the absence of oxygen. Biogas is composed mostly of methane (CH4) but also contains carbon dioxide (CO2), hydrogen sulfide (H2S), and other gases as well as water vapor.

Biogas can be used for cooking or heating purposes, similar to natural gas; however, it’s not safe enough for use in vehicles due to its high concentration of CO2 and H2S gases that make up about 10% each by volume.

Advantages of Biogas Production

Biogas production is a great way to improve your financial situation and help the environment. Here are some of the benefits of biogas production:

- Environmental Benefits: Biogas can be used as an alternative energy source that reduces carbon emissions, which are harmful to the environment. It also helps reduce waste disposal problems by converting organic matter into usable gas that can be used as fuel or fertilizer.

- Economic Benefits: When you produce your own biogas at home, you’ll save money on utility bills because it costs less than electricity or propane gas for heating purposes (if you live in an area where there isn’t access to natural gas). You’ll also be able to sell any excess energy produced by your system back into local grids through net metering programs offered by many states/provinces around the world! This means more cash in pocket each month while helping out our planet at the same time!

Disadvantages of Biogas Production

There are some disadvantages to biogas production, however. For example:

- High initial costs – Biogas systems can be expensive to install and maintain. It’s important to consider whether you have the money for this before you begin your project.

- Potential safety risks – Biogas production requires careful handling of chemicals such as methane and hydrogen sulfide (H2S). If you’re inexperienced with these materials, it may be best not to take on this project yourself unless you have access to expert help or education in their use.

- Limited availability of raw materials – Some types of waste materials aren’t suitable for biogas production because they don’t contain enough organic matter or nutrients needed by bacteria during digestion processes within anaerobic digesters (where gas is produced).

Biogas Production Process

Biogas production is a process that involves anaerobic digestion, purification, and storage.

Biogas production is a process that involves anaerobic digestion, purification, and storage.

Anaerobic digestion is the first step of biogas production. The organic matter in waste products such as food scraps or manure is broken down by microorganisms in an oxygen-free environment to produce biogas (methane) and water vapor.

Biogas purification is necessary because raw biogas contains other gases like hydrogen sulfide which can be harmful to humans if released into the atmosphere without being removed first. This can be accomplished through scrubbing devices that remove these toxic compounds from the gas stream before it enters storage tanks or pipelines for transport elsewhere on-site or offsite for use as fuel elsewhere (e.g., heating homes).

Types of Biogas

There are two types of biogas: methane-rich and carbon dioxide-rich. Methane-rich biogas is produced by anaerobic digestion of organic matter, such as animal manure or plant material. Carbon dioxide-rich biogas is produced from the fermentation of organic materials in airtight digesters that contain CO2 sources such as municipal solid waste (MSW).

Biogas Production Technologies

Biogas production can be done on a small scale or large scale. Small-scale biogas production involves using animal waste, such as cow dung and manure, to produce methane gas for cooking purposes. Large-scale biogas production involves using organic materials like agricultural waste, municipal solid waste (MSW), sewage sludge, and composted municipal solid waste (CMSS).

Biogas Utilization Technologies

Biogas utilization technologies are the methods used to convert biogas into useful energy. Biogas can be utilized in many ways, including:

- Combustion

- Gasification

- Fuel cells

Biogas Upgrading Technologies

Biogas upgrading technologies are used to increase the quality of biogas by removing unwanted components in it. The main types of biogas upgrading technologies include membrane separation, pressure swing adsorption, and chemical scrubbing.

Membrane separation uses membranes made from polymeric materials like polyvinylidene fluoride (PVDF) or polyethersulfone (PES). These materials allow only certain gases to pass through them based on their molecular size and shape. This process can be used to remove hydrogen sulfide from raw biogas streams that contain high levels of this dangerous gas; however, it’s not effective at removing carbon dioxide because its molecules are too large for the membrane pores.

Biogas Applications

Biogas can be used for many applications, including:

- Power generation. Biogas can be burned to produce heat or electricity. It’s often used as a renewable energy source because it’s produced from organic matter, which is naturally replenished.

- Transportation. The compressed natural gas (CNG) version of biogas can be used in vehicles that run on CNG instead of gasoline or diesel fuel, such as buses and trucks. This reduces greenhouse gas emissions by up to 80 percent compared with traditional fuels.

- Heating/cooking facilities: Biogas can also be converted into thermal energy through combustion or heat exchangers; this process helps provide hot water for homes and businesses as well as cooking facilities in restaurants or schools where food preparation takes place.

Conclusion

Biogas production is a sustainable and cost-effective way to generate energy. It can be used in the home, on farms, or even on a larger scale at factories and businesses. Biogas plants are relatively easy to set up and maintain, with minimal costs involved in their operation.

Biogas plants are also highly efficient at converting organic waste into methane gas and producing electricity.

English

English

German

German

French

French

Spanish

Spanish