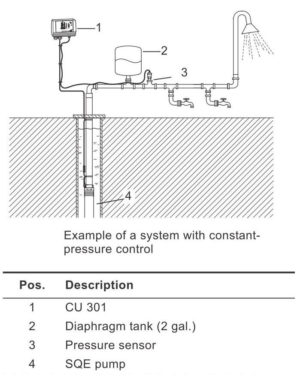

With the help of this unique unit you can get the maximum effect of the pump no matter how the water consumption varies. Grundfos CU 301 control panel together with the SQE submersible well pump provides the constant pressure of water in pipes and stable water flow. Such facilities can be used as domestic water delivery system, small water stations and irrigational networks, it is helpful in dispensing water into tanks, ecological water maintenance and even in small fuel stations.

Principle of work

The whole unit consists of:

The whole unit consists of:

- Grundfos SQE pump that provides the water from the reservoir;

- tank with diaphragm that provides proper pressure in the system;

- Grundfos pressure sensor;

- control panel CU 301.

The last receives the data from the sensor and gives commands to the pump depending on if there is a water flow and how big it is. In essence, if the pressure is high, the electronics slow the motor or stop it, and if it goes down – the motor works faster. The communication between the CU 301 and the engine goes by the mains borne, the signal in transmitted between the signal coils in control panel and pump. Electronics maintain the control over the alarm conditions in the hydraulic system based on the programmed default values of operating pressure.

Operation

Grundfos CU 301 has friendly and intuitive working panel. There are three buttons – on/off, up and down, and several indicators that show the current condition of the pump and the pressure. Optionally there can be the remote controller MI 301 that gives the possibility to configure the control panel distantly, but is not necessary to work with it.

Reliable alarm system is represented on the front panel of the CU 301 too. There is a special indicator for undesired conditions. It will let you know that:

Reliable alarm system is represented on the front panel of the CU 301 too. There is a special indicator for undesired conditions. It will let you know that:

- there is no connection with the pump;

- the sensor is not working;

- there is overload or abnormal temperature;

- speed is falling down or voltage is too high.

Control panel also has the protection from the dry run of the pump.

Grundfos CU 301 comes with the understandable and detailed instructions, following them accurately you will not run into any difficulties.

Installation

You need to choose the right location for the pressure sensor. Electronics keep the pressure stable where it is positioned, so it is highly recommended installing it closer to the point of water consumption. If you have several taps in the system, choose the one where you need stable and constant water flow, for example – shower or sink.

Keep in mind that the precharge pressure in the diaphragm tank should be set to 70% of the pressure settings. Otherwise, the CU 301 will not be able to control the flow. When the pressure sensor and the pump are positioned on their places and connected to the CU 301, you can program it and start working.

Installation menu suggests configuring the pump, sensor and control center in following parameters:

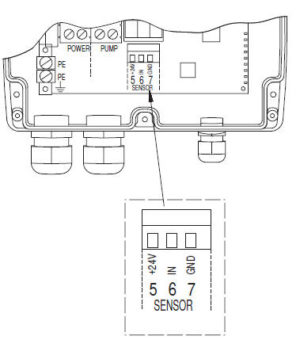

- choice and settings of the pressure sensor, such as output signal, minimum and maximum bar;

- maximum speed and pressure;

- indication mode;

- timeout of the automatic restart;

- dry-running stop value, which has to be set accordingly to the type of the motor you use;

- activation or disabling the buttons.

You will also have to assign the number to your CU 301 control panel and the motor, they should coincide. Otherwise, “No connection to pump” alarm will be indicated.

As it was said before, everything is simple if you read and follow the manual included.

English

English

German

German

French

French

Spanish

Spanish