Grundfos has various pump models that allow easily get the water from the underground. However, not all of them can be equipped with a control panel, which allows conveniently to operate the pump. The SQE series allows clients to install Grundfos CU 300 and CU 301 control panels. In the event of a pump failure on the panel information from the CU 300 or CU 301, the pump alarm light is activated, which allows you to deal with the issue quite fast.

With the Grundfos GO wireless device, you can even monitor and adjust the pump settings remotely. Therefore, it is important to consider the peculiarities of CU 300 and CU 301 in order to choose the most suitable option. In general, they are the same as some personal specific features.

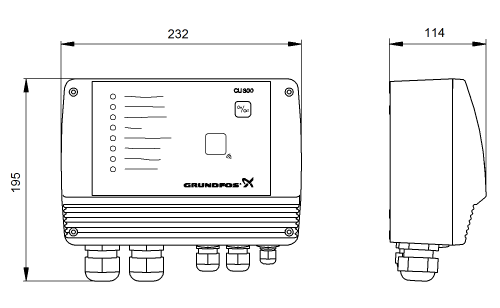

Grundfos CU 300 Control Panel

The CU 300 control unit is designed to control and regulate Grundfos SQE borehole pumps operating at constant pressure. This module monitors the electricity consumption, speed and operating time of the SQE pump, emptying, restarting, and system pressure. The CU 300 has the following functions:

- Easy adjustment according to the characteristics of the hydraulic system;

- Full control of the SQE pumps.

Two-way communication with the SQE pumps

Alarm indication of the pump operation via LEDs located on the front panel. You are able to switch on, switch off or reset the pump settings with a button, the Grundfos CU 300 communicates with the pump via a network cable (wired HF communication), so there is no need for an additional cable.

Possible alarms

- No communication

- Overvoltage

- Undervoltage

- Dry running

- Decrease speed

- Overheating

- Overload

- Sensor alarm

The Grundfos CU 300 includes inputs for two analog sensors and one digital sensor. The relay output for external alarm indication and a control system powered by input signals such as flow, pressure, water level, and conductivity. In addition, CU 300 enables remote control.

Remote control MI301

You can manipulate CU 300 remotely using the MI301. It allows you to manage all the parameters of the pump without going to the control panel.

Functions of the MI301

Control of the hydraulic system by displaying the following actual parameters:

- Power consumption

- Electricity consumption

- Operating time

Change of factory settings. Adjustable parameters:

- Speed (flow rate)

- Constant pressure regulation mode

- Emptying function

- Automatic restart time

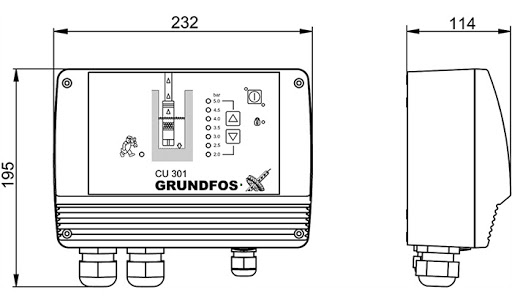

Grundfos CU 301 Control Panel

The Grundfos CU 301 control unit has been specially designed for Grundfos SQE borehole pumps. CU 301 is comfortable and ergonomic. Blocking against accidental pressing is done by double pressing 2 buttons. The pressure created in the system is easily regulated. The red LED light informs us about errors or accidents, the green one – about readiness for work or normal functioning of the system. Using the CU 301 allows:

- Provide constant pressure with variable water demand.

- Adjust the required system pressure.

- Control the main parameters of the pump and display the indication on the panel.

The MSE 3 motors on the SQE pumps allow speed control within 65-100% of their range. This makes it possible to select any operating point (flow-pressure) within this operating range.

The Grundfos CU 301 must not be connected to a standard SQ pump. It is the CU 301 that allows the SQE pump speed to be constantly adjusted so that the network pressure always remains constant at variable flow rates. No special knowledge is required to connect and configure the Grundfos CU 301. A minimum of settings and buttons with a flawless operation of the entire system from one supplier.

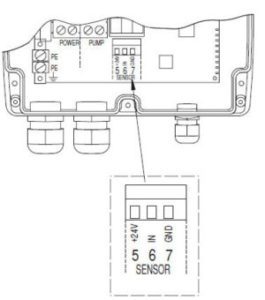

The CU 301 exchanges signal with the pump via the pump power cable and do not need an additional cable. To operate the unit in conjunction with a pump, an external pressure sensor and a hydraulic accumulator (albeit of a minimum volume) must be used.

Pressure Sensor

The pressure sensor registers the pressure values and transmits this signal to the CU 301, which compares the data with the setpoint and smoothly changes the pump speed. It is advisable to connect the unit to the sensor with a shielded cable. However, this can be avoided if the length of this cable is reduced to the minimum possible. It is advisable to place the CU 301 in a dry room, next to the pressure sensor and hydraulic accumulator installed on the pipeline.

The pressure sensor registers the pressure values and transmits this signal to the CU 301, which compares the data with the setpoint and smoothly changes the pump speed. It is advisable to connect the unit to the sensor with a shielded cable. However, this can be avoided if the length of this cable is reduced to the minimum possible. It is advisable to place the CU 301 in a dry room, next to the pressure sensor and hydraulic accumulator installed on the pipeline.

Pump Speed

The pump speed is constantly monitored and adjusted to the pressure set by the user. This also provides energy savings at low water consumption, since the pump does not run at full capacity. The pressure required by the user can be changed at any time (but, of course, within the hydraulic capabilities of the pump).

The CU 301 issues a pump start command in the following two cases:

When the pressure in the system drops at a rate of more than 0.1 bar/s.

It is logical that the rate of pressure drop depends on the volume of the accumulator. For example, when using an 8-liter tank, the indicated pressure drop rate is achieved at a flow rate of 0.18 m³/h. With a larger tank volume, the flow rate should be higher.

When the pressure in the system drops by 0.5 bar below the preset for maintenance.

When the pump is running, the speed varies to provide a user-set pressure of ± 0.2 bar. However, if the flow rate changes too abruptly, the pressure fluctuations can be large.

The pump is turned off after the end of water consumption. The pump continues to run until the pressure exceeds the set value by 0.5 bar. In this case, the unit smoothly reduces the pump speed and at the same time registers the pressure change in the system. If with decreasing frequency, the pressure drop is not detected, the pump is switched off.

The CU 301 has a pressure regulation range of 2 to 5 bar (in 0.5 bar increments).

Using With MI301

Using the Grundfos MI301 gives additional functionality to the CU 301. It is possible to set additional parameters and display modes and characteristics. For example, you can set other values of the current, voltage, and signal range for the pressure sensor, find out the pump speed, power consumption, operating time, number of starts, fine-tune the parameters of dry-running protection, etc. The device can be operated and without MI301.

Difference Between Grundfos CU 300 and CU 301

If you take a look at CU 300 and CU 301 you would notice that they are different in design. However, they are different in functions and simplicity of use.

The main difference is that the CU 301 is only intended for regulating and monitoring system pressure. It is simplified as much as possible so that an ordinary user can operate the pump at home. The CU 301 control panel does not require obligatory MI301 and you are able to manage its settings manually. On the CU 301 unit, you will have buttons to turn on/off the pump and to adjust the pressure. Other LED lights are no longer simply listed. There is a scheme of the pump that allows you to receive information about where has occurred an issue and whether it requires a technician to check it or not.

The CU 300 is a more professional tool with more flexible pump control options by connecting more controls. With the CU 300, it is possible to program a variety of scenarios considering pressure, flow, level, conductivity, and other parameters. It has LED indicators of the pump status. On the CU 300 unit, you will have only a button to turn on/off the pump. MI301 is required to program the CU 300.

Conclusion

Each control panel has to be installed with an SQE pump. While making a choice it is important to consider your actual requirements and funds that you are able to spend. In case you would like to get more information on them it is better to get in touch with a Grundfos representative, who will be able to answer all your non-standard questions.

English

English

German

German

French

French

Spanish

Spanish